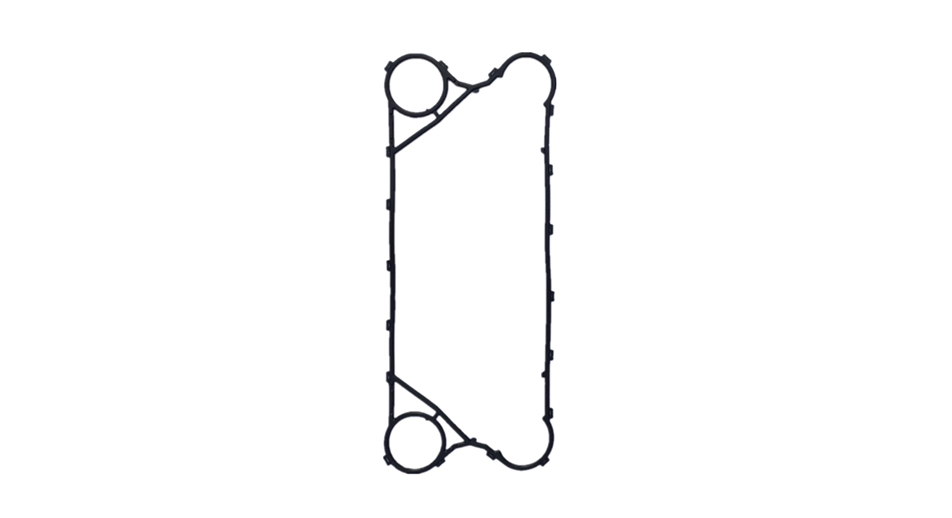

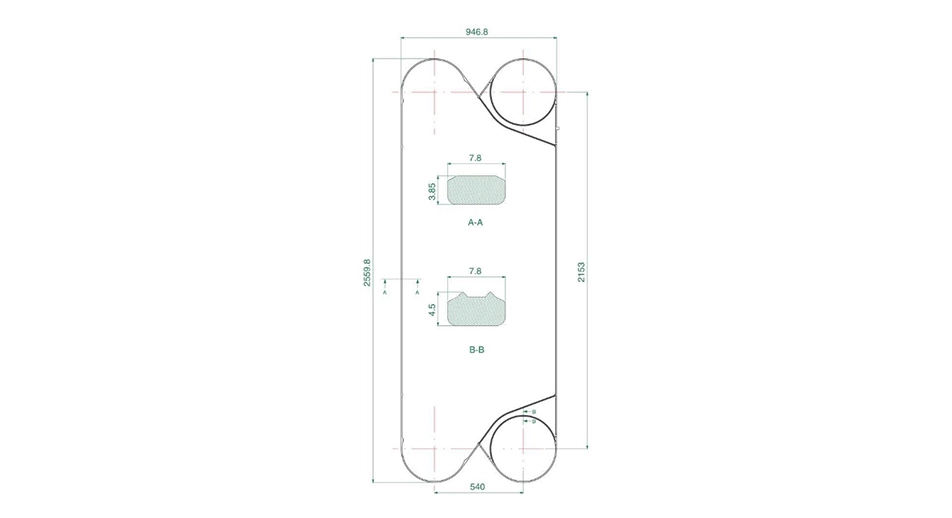

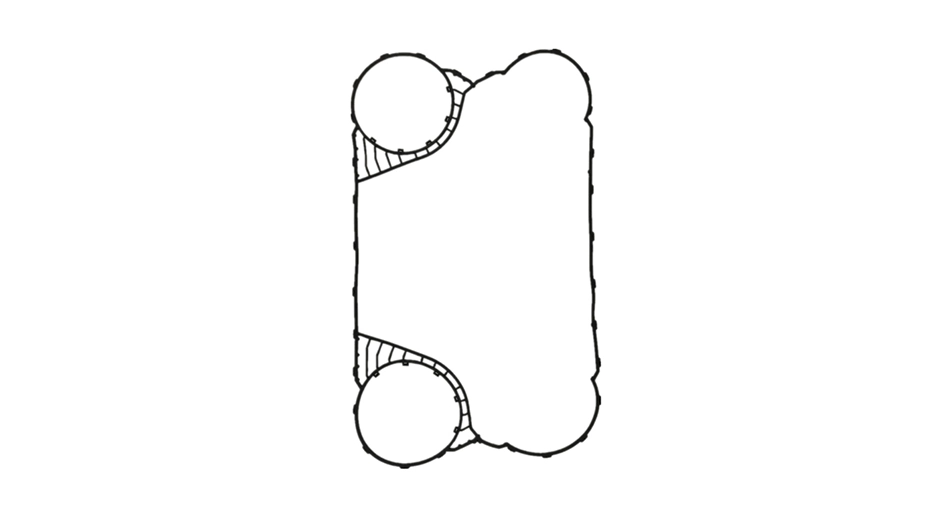

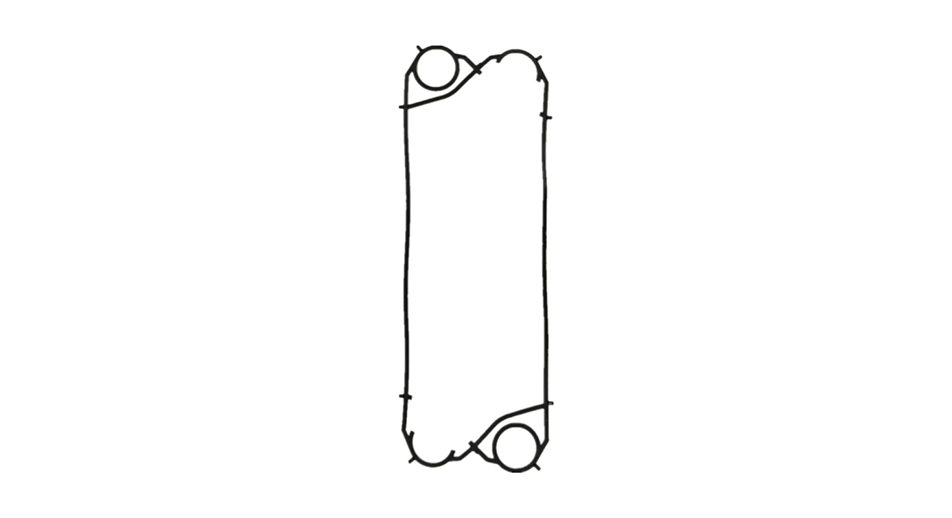

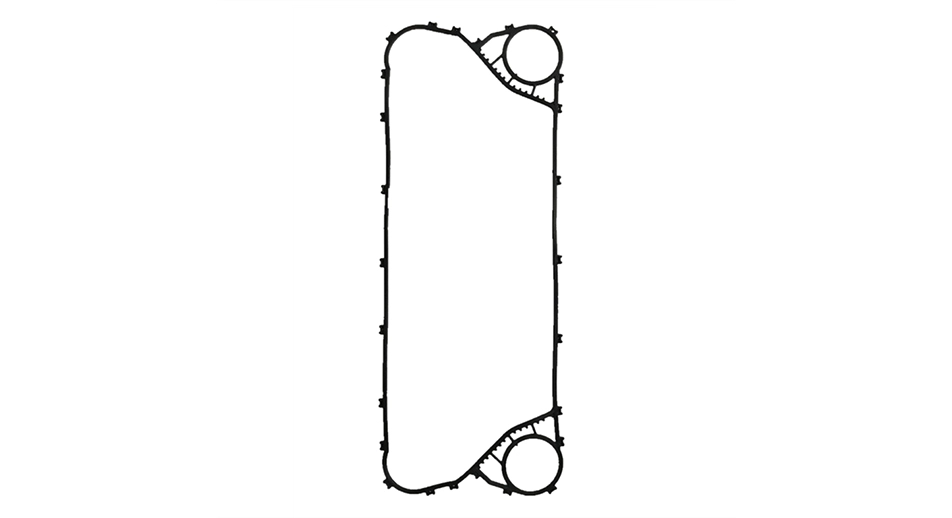

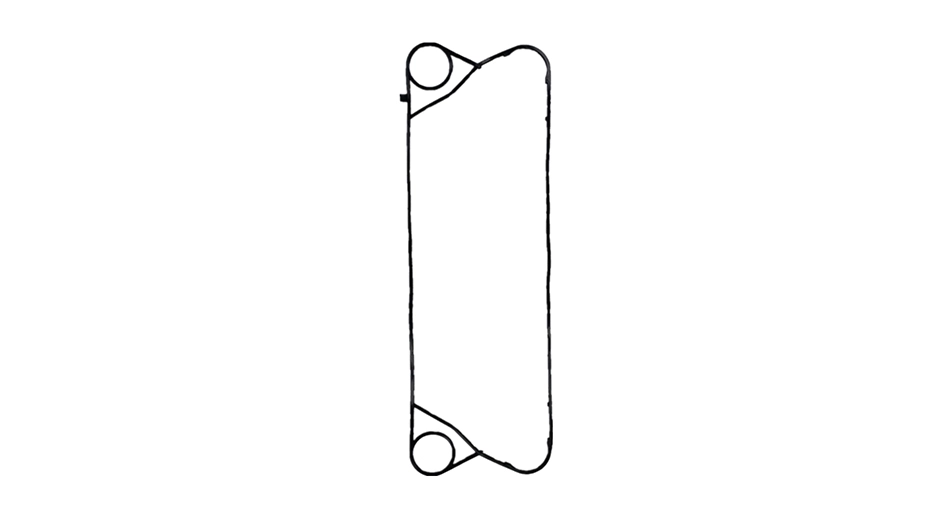

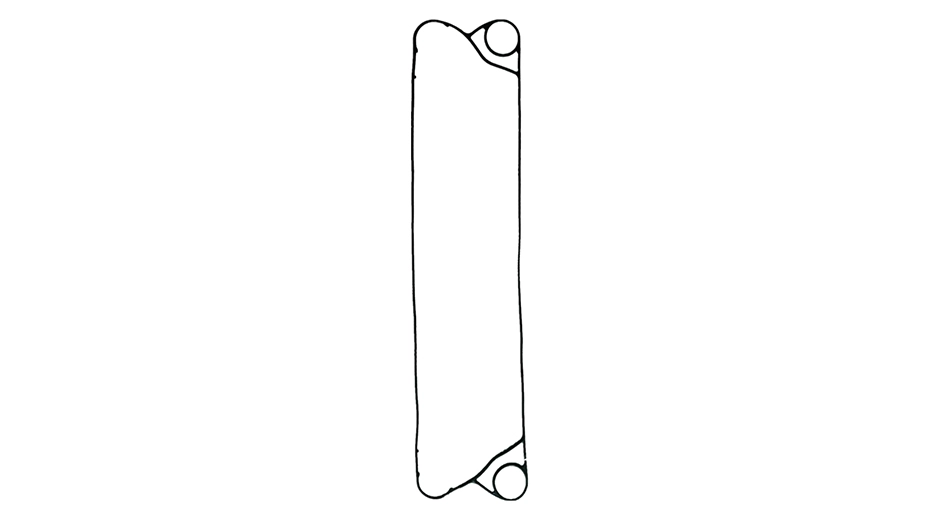

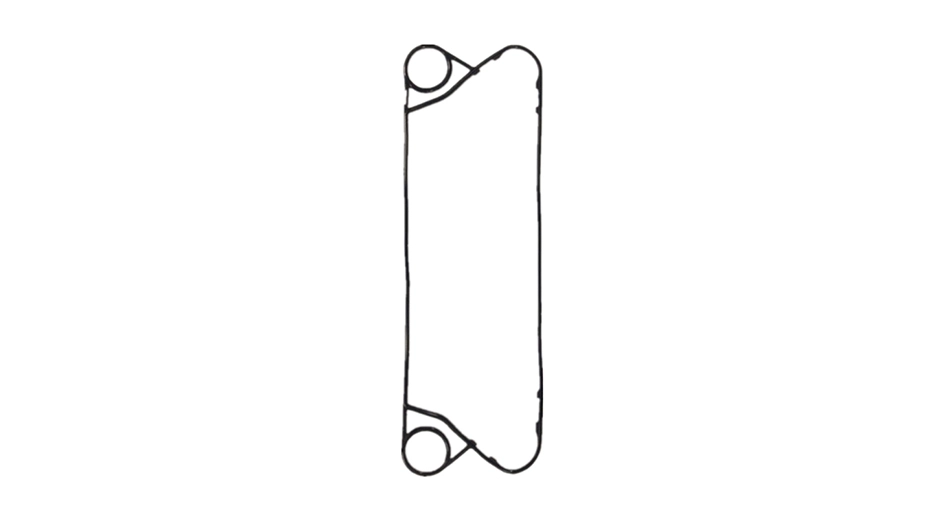

Heat exchanger gaskets are crucial for maintaining the integrity of the heat exchanger system, preventing cross-contamination and optimizing heat transfer efficiency. Regular inspection and replacement of gaskets is necessary to ensure reliable and safe operation of heat exchangers in industries such as chemical processing, HVAC, refrigeration, and power generation.

Elastomeric gaskets are made from rubber-like materials such as Nitrile (Buna-N), EPDM (Ethylene Propylene Diene Monomer), and Viton (Fluoroelastomer). These gaskets offer excellent sealing properties, flexibility, and resistance to a wide range of fluids and temperatures. Elastomeric gaskets are commonly used in applications involving water, oils, and non-corrosive fluids.

Polytetrafluoroethylene (PTFE) gaskets, also known as Teflon gaskets, are used in heat exchangers handling aggressive chemicals, corrosive fluids, or high-temperature applications. PTFE has excellent chemical resistance and can withstand extreme temperatures. It provides a reliable and chemically inert sealing solution, ensuring compatibility with a wide range of aggressive fluids.

Graphite gaskets are employed in heat exchangers operating at high temperatures and under high-pressure conditions. Graphite exhibits excellent thermal conductivity and can withstand extreme temperatures. It offers good resistance to various chemicals and is suitable for applications involving steam, hot oils, and corrosive fluids.

Tel

Tel